I’m on an in a single day flight from New York to Frankfurt, Germany, and the accoutrements given to me in enterprise class have a sustainable sheen. Each the polyester blanket and polyester flight equipment proudly declare they’re made of material spun from recycled plastic bottles.

However doesn’t United Airways know that recycled bottles are so yesterday’s inexperienced materials? No, the brand new scorching and hyped know-how is recycling polyester into polyester. And I’m on my technique to observe probably the most well-capitalized innovation on this burgeoning area, a chemical recycling course of by a brand new startup, Reju.

Solely a half hour exterior downtown Frankfurt at a colorless industrial park are Reju’s short-term workplace and three half-constructed buildings that can function its industrial operations. Within the center shall be R&D and training, to the suitable is the depolymerization plant, and to the left would be the repolymerization plant.

Plastics, together with polyester, are shaped by taking particular person chemical compounds known as monomers and forming them into chains to create polymers. Primarily, Reju’s course of breaks the polyester down into its constituent chemical compounds (depolymerization) then places it again collectively in a series once more (repolymerization).

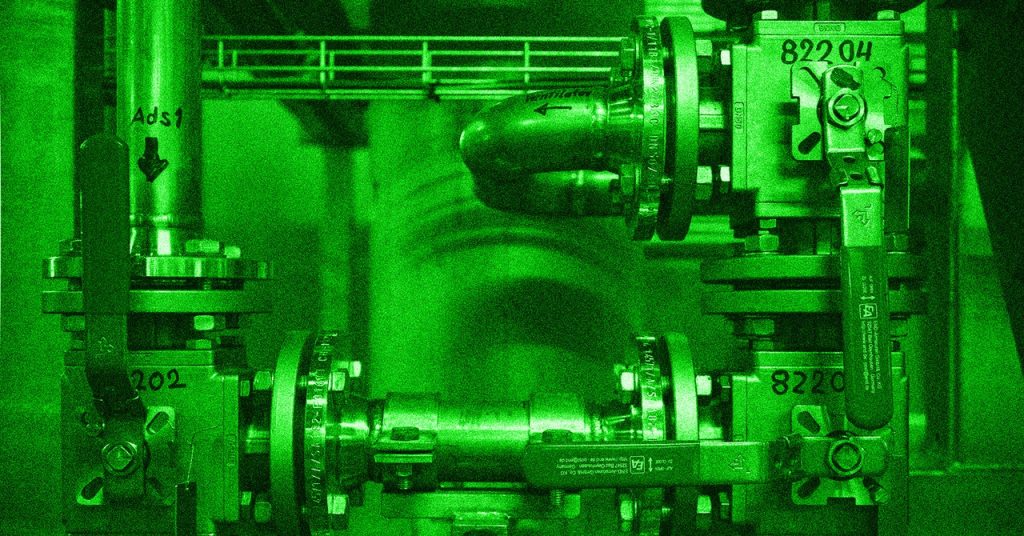

I swimsuit up in a tough hat, vest, security glasses, and sneakers, together with a half dozen different journalists and influencers to see contained in the depolymerization plant, the place the magic occurs. (Reju hosted me on this journey and coated my journey prices.) Silver pipes snake all over the place into small silos, and from our vantage level on the bottom ground, we are able to search for via the metallic grates and thru the heart of panels and ducts to the highest of the four-story constructing. Males in denims and high-visibility vests wander the plant, casually tinkering with the settings on varied items of equipment, calling in German to one another.

As I’ve reported earlier than, the style business is dissatisfied with the present polyester recycling paradigm. Simply 0.3 % of supplies utilized in style are from recycled sources, and of that, it is just about all water bottles.

You see, polyester is the very same as PET plastic utilized in water bottles, simply in a special form (threads as a substitute of a bottle). Mechanically recycling PET—melting it down and re-extruding it—isn’t ideally suited, as a result of the method degrades the standard of the plastic, making it much less pliable and high-performance. It additionally requires pure, undyed PET, with the clear plastic bottle being the paragon. And polyester textiles are by no means pure polyester.

The most typical mixture of supplies you’ll discover in previous clothes is 70 % polyester, 30 % cotton. “However whenever you go into the small print, it’s truly 60 % PET, 5 % dyes, 2 % elastane, perhaps comprises a little bit little bit of nylon. Who is aware of?“ says Antoni Mairata, the chief know-how officer at Reju, as he prepares us to stroll via the manufacturing unit.

My earlier reporting has proven that polyester can even comprise plasticizers like BPA, metals resembling antimony, poisonous PFAS, and extra undesirable contaminants it picked up because it moved the world over via factories, warehouses, and container ships. Because of this we feed tens of millions of clear, food-grade water bottles into recycling crops, whereas dumping previous polyester clothes into landfills.